Granite is a timeless material that exudes luxury, durability, and beauty. Whether it’s for countertops, flooring, or decorative elements, granite enhances the aesthetic appeal of any space.

However, cutting granite can be tricky and requires precision to ensure the stone remains undamaged. This is where water jet cutting technology steps in—a revolutionary method that allows for flawless, efficient, and precise cutting of granite.

In this blog, we’ll explore everything you need to know about water jet cutting granite, including its benefits, challenges, use cases, and how to choose the right service for your granite-cutting needs.

Can Water Jet Cut Granite?

Yes, a water jet can cut granite with incredible precision and efficiency. This technology uses a highly pressurized jet of water, often combined with an abrasive material like garnet, to slice through tough materials such as granite.

Unlike traditional cutting methods that can cause chips, cracks, or other forms of damage, water jet cutting ensures clean, smooth cuts without compromising the stone’s structural integrity. This non-invasive method is ideal for intricate designs, ensuring the granite’s natural beauty and durability are preserved.

Here’s how it works:

- A water jet system propels water at pressures up to 90,000 psi (pounds per square inch).

- When combined with abrasives, this high-pressure water can cut through even the most rigid materials like granite effortlessly.

- The process doesn’t generate heat, which means there’s no risk of warping or weakening the stone.

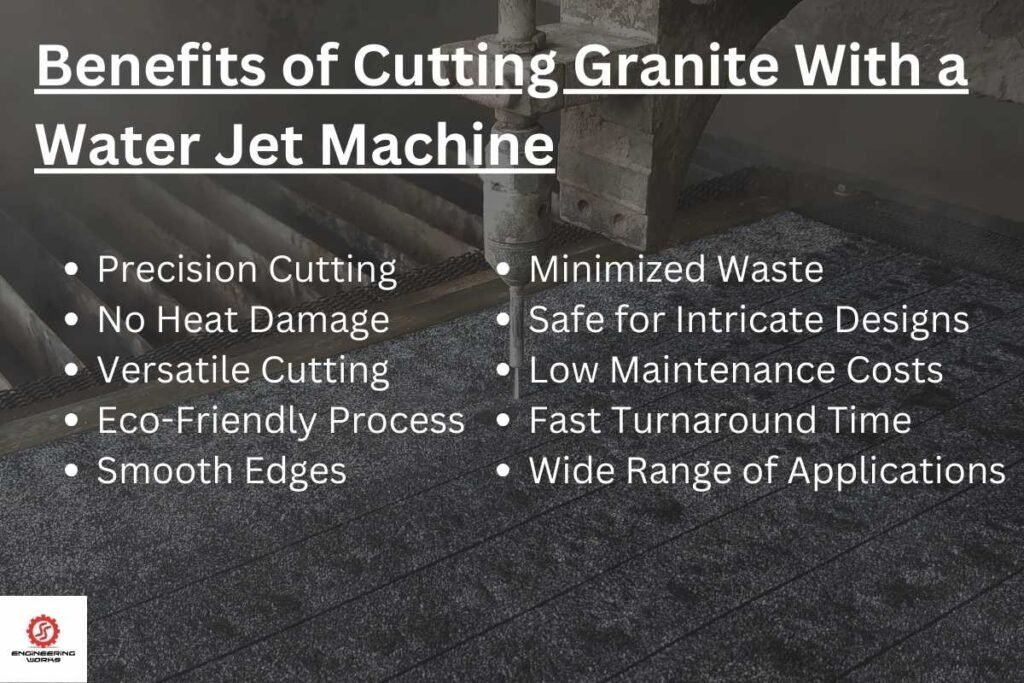

What Are the Benefits of Cutting Granite With a Water Jet Machine?

Cutting granite using a water jet cutting machine offers numerous advantages compared to traditional cutting methods. Here are 10 key benefits

The above image is nothing but an image of the benefit of waterjet cutting for granite

1. Precision Cutting

Water jet machines deliver exceptional accuracy, allowing for intricate patterns, curves, and edges to be cut with ease.

2. No Heat Damage

Unlike laser or mechanical cutting, water jet cutting is a cold process, ensuring the granite’s structure and natural finish remain intact without heat-induced stress or cracks.

3. Versatile Cutting

Water jets can cut through granite of varying thicknesses, making them suitable for thin tiles as well as large slabs

4. Eco-Friendly Process

Water jet cutting is an environmentally friendly process as it uses water and abrasive materials, leaving no harmful emissions or chemical residues.

5. Smooth Edges

With water jet technology, you get clean, burr-free edges that require little to no additional finishing, saving time and effort.

6. Minimized Waste

The precision of water jet cutting minimizes material wastage, which is particularly important when working with expensive materials like granite.

7. Safe for Intricate Designs

Whether you’re creating decorative patterns or cutting out complex shapes, water jets can handle detailed designs without damaging the stone.

8. Low Maintenance Costs

Water jet machines have fewer wear-and-tear components, resulting in lower maintenance costs over time compared to traditional cutting tools.

9. Fast Turnaround Time

The efficiency of water jet machines allows for quicker project completion, even for large-scale granite-cutting jobs.

10. Wide Range of Applications

Beyond granite, water jets can cut a variety of materials, making them a versatile solution for diverse projects.

What are the use cases for waterjet granite cutting?

Waterjet granite cutting is used across various industries and applications due to its precision and efficiency.

Here are some of the most common use cases:

1. Granite Countertops

Water jets are widely used to create smooth, polished countertops with custom edges and sink cutouts.

2. Flooring Tiles

Intricate flooring designs and patterns can be achieved using water jet cutting, ensuring perfect alignment and finish.

3. Wall Claddings

Architectural projects often use granite wall claddings, and water jets enable precise cuts for seamless installations.

4. Monuments and Memorials

Intricate carvings, engravings, and lettering on granite monuments or memorials are achieved using water jet machines.

5. Decorative Art

Designers and artists use water jets to create stunning granite sculptures, medallions, and inlay designs.

6. Staircases

Water jets can cut granite for stair treads and risers, ensuring uniformity and smooth finishes.

7. Custom Projects

From signage to custom tabletops, water jet cutting is ideal for bespoke granite creations.

Can You Cut Stones With a Water Jet?

Yes, stones can be cut with a water jet cutting machine, including rigid materials like granite, marble, quartz, and limestone. The versatility of water jet cutting makes it one of the best methods for cutting through different types of stone with precision and minimal damage.

Whether you’re working on granite countertops, marble flooring, or custom stone designs, water jet cutting is the ideal method to achieve precise, damage-free results.

Here’s how water jet cutting works for stones:

- High-Pressure Water Jet: The machine uses a concentrated jet of water at extremely high pressures, often reaching 90,000 psi. This ensures the water is powerful enough to cut through even the hardest stones.

- Abrasive Additives: For dense stones like granite, an abrasive material (typically garnet) is mixed into the water jet. This abrasive enhances the cutting ability, allowing for smooth and precise cuts.

- Cold Cutting Process: Unlike traditional methods like sawing, water jet cutting doesn’t generate heat, meaning the stone won’t suffer thermal cracks, warping, or discoloration.

Why Use Water Jet Cutting for Stones?

- Minimal Damage: Traditional cutting methods can cause fractures or chips, but water jets ensure a clean cut without damaging the stone.

- Uniform Edges: The process produces smooth, finished edges that require little to no post-processing.

- Versatility: From soft stones like sandstone to hard stones like granite, water jet cutting can handle all types of stones efficiently.

- Environmental Benefits: It’s a clean process with no harmful emissions, making it eco-friendly.

What Are the Challenges in Waterjet Cutting for Granite?

While water jet cutting is a highly advanced and effective technology, cutting granite does come with a few challenges. Understanding these challenges is crucial to ensure accurate results and minimal wastage.

- Abrasive Cost: Granite is a tough material, which means that abrasive materials like garnet are needed for cutting. These abrasives can increase the cost of the process, especially for large projects requiring substantial amounts of abrasive.

- Water Pressure Consistency: Maintaining consistent water pressure is critical during water jet cutting. Any fluctuations in pressure can lead to uneven cuts, especially in thicker granite slabs. It requires highly maintained equipment and experienced operators.

- Material Thickness: While water jet cutting can handle granite of various thicknesses, cutting extremely thick slabs may require multiple passes or slower cutting speeds. This can increase cutting time and costs.

- Skill and Expertise: The process of water jet cutting granite requires skilled operators to ensure precision. Improper handling of the machine can result in errors, uneven edges, or even wasted material.

- Initial Investment in Equipment: The equipment for water jet cutting is expensive to set up. This cost is reflected in the pricing of services, especially for smaller projects.

- Water Usage: The process consumes significant amounts of water, which may need proper filtration and recycling systems to avoid wastage.

How to Choose the Best Waterjet Cutting Service for Granite?

Choosing the right water jet cutting service is crucial for achieving high-quality results, especially when working with expensive and delicate materials like granite.

Here are some tips to help you find the best service provider:

- Experience and Expertise: Look for companies that specialize in water jet cutting, especially for granite. Experienced providers have the knowledge and skills to handle complex projects and intricate designs.

- Advanced Equipment: Ensure the service provider uses state-of-the-art water jet cutting machines. Modern equipment ensures precise, smooth cuts with minimal material wastage.

- Customization Options: Granite cutting often involves unique patterns, curves, and designs. Choose a service provider that can handle custom requests and intricate detailing.

- Fast Turnaround Times: Time is critical for many projects. A reliable water jet cutting service should have the capacity to complete jobs efficiently without compromising on quality.

- Customer Reviews and Testimonials: Check online reviews and customer testimonials to ensure the company is reputable and delivers satisfactory results.

- Geographic Reach: If you’re in India, SS Engineering Works offers water jet cutting services for granite in multiple cities, including Coimbatore, Bangalore, Chennai, and Kerala. With a wide service area, we make it convenient for customers to access high-quality granite cutting services.

- Affordable Pricing: Compare pricing across different providers, but don’t compromise on quality. Choose a company that offers competitive rates while delivering top-notch results.

Choose us for top-quality waterjet cutting services! We offer precise, reliable cutting solutions for all, with fast and dependable delivery

Where Can You Achieve a Clean Cut for Your Granite?

For precise and clean granite cutting, trust SS Engineering Works. With our advanced water jet cutting technology, we ensure flawless results for all your granite cutting needs.

Why Choose SS Engineering Works?

- Experienced Team: Our skilled professionals have years of experience in water jet cutting, ensuring precision and accuracy for every project.

- Modern Equipment: We use cutting-edge water jet cutting machines to deliver smooth, damage-free cuts that preserve the beauty and durability of your granite.

- Custom Solutions: Whether it’s countertops, flooring, or decorative designs, we specialize in creating custom pieces that meet your specific requirements.

- Wide Service Area: We serve customers across India, including major cities like Coimbatore, Bangalore, Chennai, and Kerala. No matter where you are, we’re here to provide reliable granite cutting services.

- Fast Turnaround and Affordable Pricing: We value your time and budget, offering efficient services without compromising on quality.

Conclusion

Cutting granite requires precision, care, and advanced technology, and water jet cutting is the ideal solution for achieving flawless results. Whether you’re working on intricate designs or large-scale projects, partnering with the right service provider is essential.

SS Engineering Works offers expert water jet cutting services in Coimbatore, Bangalore, Chennai, Kerala, and beyond. With our modern equipment, skilled team, and commitment to quality, we ensure your granite cutting needs are met with precision and professionalism.

Reach out to us today to get started on your granite cutting project and experience the unmatched benefits of water jet cutting!

FAQs

Yes, waterjet cutting is suitable for all types of granite, whether it’s soft, hard, or dense. The high-pressure water combined with abrasives can precisely cut through any granite slab, regardless of its thickness or hardness, while preserving its natural beauty and structure.

Absolutely! Waterjet cutting is superior to traditional methods because it delivers precise cuts without causing chips, cracks, or heat damage. Unlike saws or lasers, the cold-cutting process ensures the granite’s integrity remains intact, producing clean, smooth edges with minimal material wastage.

A waterjet cutting machine can cut granite slabs up to 12 inches thick, depending on the equipment and abrasives used. This makes it ideal for a wide range of applications, from thin tiles to large architectural slabs.

No, waterjet cutting is an eco-friendly process. It uses only water and abrasives like garnet, which are non-toxic and recyclable. Additionally, the precision of the technology minimizes material wastage, making it both cost-effective and environmentally responsible.