Water jet cutting is a versatile and precise method to cut a wide range of materials, from thin metal sheets to thick, heavy materials like stone. Its ability to make accurate cuts with minimal waste has made it a popular choice in various industries.

But what about wood? Is water jet cutting wood possible?

This blog will explore how water jet cutting works for wood, the factors to consider, and why it’s an excellent choice for wood-based projects.

Can Water Jet Cut Wood?

Yes, water jet cutting machines can cut wood with precision and ease. Using a water jet cutting machine to cut wood is one of the best methods to achieve the perfect cut. The high-pressure water jet ensures clean, accurate edges without burning or fraying the material. This makes it ideal for intricate designs and detailed woodwork projects.

What Key Factors Should You Consider When Water Jet Cutting Wood?

Several factors come into play when using water jet cutting for wood to ensure optimal results. By carefully considering these factors, water jet cutting can be optimized to produce outstanding results for all types of wood, from intricate designs to bulk-cutting projects.

Here’s what you need to consider:

1. Wood Type and Density

The type and density of wood greatly influence the water jet-cutting process. Hardwoods like oak, maple, and walnut are denser, requiring higher water jet pressure for precise cuts. Softer woods such as pine or cedar can be cut at lower pressures, but they may also absorb water more efficiently, so adjustments in the cutting settings are critical.

Engineered woods like MDF or plywood have different cutting characteristics due to their composite structure. Water jet cutting is versatile enough to handle these variations, ensuring clean and accurate results regardless of the material.

2. Water Pressure and Flow Rate

Adjusting water pressure and flow rate is vital in water jet cutting wood. High-pressure water jets (usually around 60,000 PSI or more) are necessary for denser or thicker woods. However, reducing the pressure can help avoid unnecessary damage or splintering for thinner or softer wood materials.

Flow rate also plays a role, as it determines the speed and efficiency of the cutting process. Fine-tuning these parameters ensures the wood is cut cleanly without damaging its edges.

3. Uneven Edges

One of the common challenges with wood cutting is achieving perfectly smooth edges, especially in intricate designs. Uneven edges can occur if the cutting pressure is not calibrated correctly. Water jet cutting minimizes this risk by delivering consistent pressure across the material, ensuring even cuts.

For detailed or decorative projects, the smooth edges achieved through water jet cutting significantly reduce or eliminate the need for post-processing like sanding or trimming.

4. Water Pressure

Wood is a porous material that absorbs water during the cutting process. While water jet cutting uses high-pressure water, it is essential to manage water absorption to prevent swelling or warping. Using specific settings to control the water pressure and adding abrasives when necessary can mitigate this issue.

Additionally, water jet cutting operates with such precision that the amount of water absorbed is minimal, preserving the wood’s structural integrity and appearance.

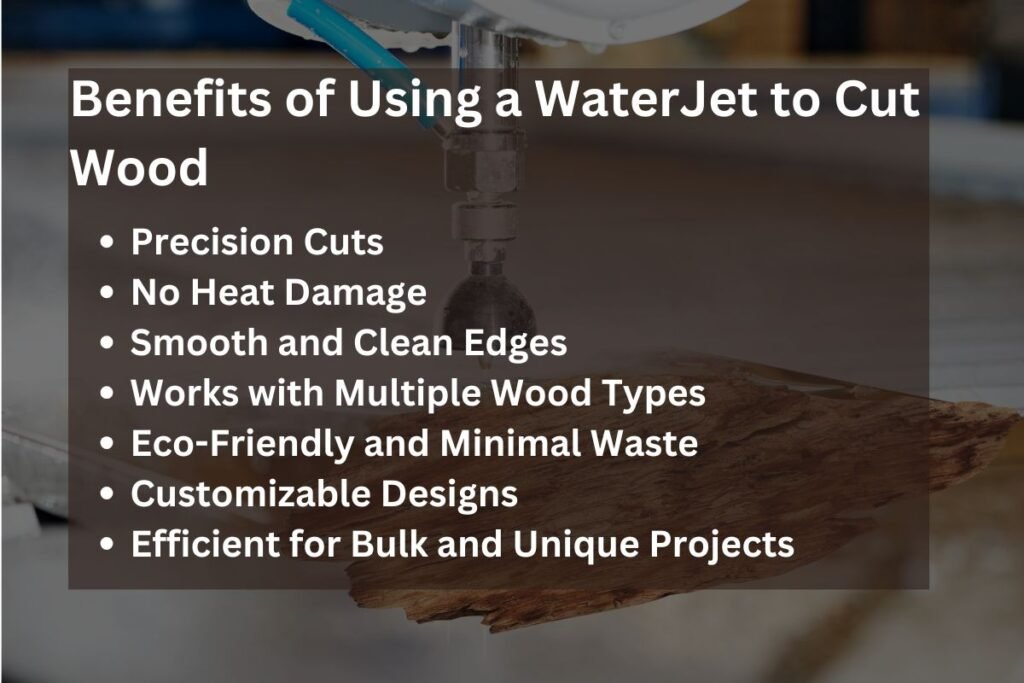

What Are the Benefits of Using a Water Jet to Cut Wood?

Water jet cutting offers numerous advantages when it comes to cutting wood. Here are some key benefits:

- Precision Cuts: Water jet cutting provides unmatched accuracy, allowing intricate designs, patterns, and detailed shapes to be cut effortlessly. The precision is unparalleled, whether for decorative purposes or complex structural designs.

- No Heat Damage: Unlike laser or traditional cutting methods, water jet cutting doesn’t generate heat. This eliminates the risk of burns, warping, or discoloration, ensuring the wood retains its natural appearance and structural integrity.

- Smooth and Clean Edges: The high-pressure water jet ensures that the edges of the cut are soft and clean, reducing or eliminating the need for post-cut finishing processes. This is particularly beneficial for projects requiring polished results.

- Works with Multiple Wood Types: Water jet cutting can handle various materials consistently, from solid wood and veneers to engineered wood like plywood and MDF.

- Eco-Friendly and Minimal Waste: With its precision, water jet cutting minimizes material wastage. This efficiency reduces costs and makes it an environmentally friendly option.

- Customizable Designs: Water jet cutting machines can be programmed for specific patterns and designs, making them suitable for custom woodwork, intricate detailing, and artistic projects.

- Efficient for Bulk and Unique Projects: Whether producing a one-of-a-kind artistic piece or a large batch of identical components, water jet cutting ensures speed and consistency.

Can You Water Jet Plywood?

Yes, you can use water jet cutting for plywood. Plywood, being a layered material, is susceptible to water damage. However, plywood remains unaffected by water during the cutting process thanks to the high-pressure nature of water jet cutting. The pressure ensures the layers stay intact, resulting in clean and precise cuts without delamination or swelling. Whether for furniture, decorative panels, or construction, water jet cutting is reliable for plywood projects.

How Thick Can a Water Jet Cut Wood?

Water jet cutting can handle varying wood thicknesses, depending on the machine’s capacity. Typically, water jet cutting can cut wood up to 12 inches thick. However, most projects involve cutting wood up to 6 inches thick for optimal precision and efficiency. The exact thickness will depend on the type of wood and the desired cutting results.

What Cannot Be Cut by a Water Jet?

While water jet cutting is incredibly versatile, there are a few materials it cannot handle effectively. While water jet cutting is excellent for most wood-based projects, certain exotic woods or heavily treated materials might require specific adjustments to achieve the best results.

Consulting with a professional service like SS Engineering Works ensures you understand the feasibility of your particular material for water jet cutting.

How to Cut Wood with Water Jet Cutting?

At SS Engineering Works, we specialize in water jet cutting services for wood and various other materials. Our experienced team ensures precise results for all your projects, whether furniture, artistic designs, or industrial components.

Our water jet-cutting services are available in multiple cities, including Coimbatore, Chennai, Kerala, and Bangalore. With advanced technology and a commitment to quality, we deliver exceptional results tailored to your needs.

To cut wood effectively with water jet cutting, follow these key steps:

- Choose the Right Machine Settings: Ensure that the water pressure and flow rate are optimized for the type of wood and its thickness. This step is critical to achieving clean and precise cuts.

- Use Abrasives if Necessary: For denser or thicker wood, adding abrasives to the water jet stream can enhance the cutting process and ensure smooth edges.

- Secure the Material: Properly secure the wood to prevent movement during cutting, which could compromise accuracy.

- Work with Experts: Partnering with a professional service like SS Engineering Works ensures your project benefits from state-of-the-art equipment and skilled technicians.

Conclusion:

Water jet cutting is possible for wood and is one of the best methods to achieve precision and clean edges. From cutting intricate patterns to working with thick or layered materials like plywood, water jet cutting excels in various applications.

Consider SS Engineering Works for all your water jet cutting needs and experience the difference in professional-grade cutting services.

Contact us today to learn how we can assist with your next project!

FAQs

Water jet cutting does not damage wood as it uses a cold-cutting process. The absence of heat ensures no burns, warping, or discoloration, making it an ideal method for preserving the wood’s natural appearance and properties.

Water jet cutting works well with various types of wood, including solid wood like oak or pine, engineered wood such as MDF, plywood, and even veneers. This versatility ensures consistent results across different wood types.

In most cases, water jet cutting produces smooth and clean edges, reducing or eliminating the need for additional finishing. The clean cuts achieved through water jet cutting are often sufficient for projects requiring polished or decorative edges.

Water jet cutting minimizes material wastage due to its precision and does not produce harmful fumes or emissions. It’s an eco-friendly option, especially with sustainable materials like wood.

You can contact SS Engineering Works for high-quality water jet cutting services in cities like Coimbatore, Chennai, Kerala, and Bangalore. We provide customized solutions for various projects, ensuring precise and efficient results tailored to your needs.